A synchronous generator is an electrical machine that converts mechanical energy into electrical energy in the form of alternating current (AC), with its rotor spinning at the same frequency as the generated AC voltage. It is widely used in power plants to generate electricity.

How a Synchronous Generator Works

- Mechanical Energy Input: A prime mover (such as a gas engine, steam turbine, gas turbine, or water turbine) drives the rotor.

- Magnetic Field Generation: The rotor has electromagnets (excited by a DC source) that create a rotating magnetic field.

- AC Voltage Induction: As the rotor spins, its magnetic field cuts through the stator windings, inducing an AC voltage.

- Synchronous Speed: The rotor rotates at a constant speed, called synchronous speed, determined by the equation:

Ns = (120 × f) / P

- Ns = Synchronous speed (RPM)

- f = Frequency of AC (Hz)

- P = Number of poles in the generator

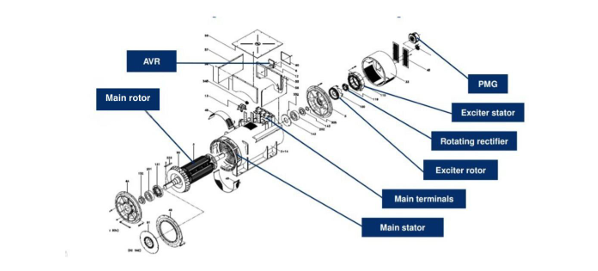

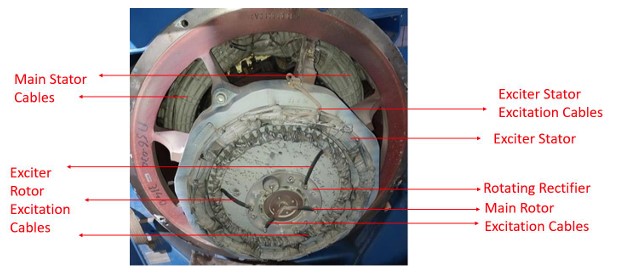

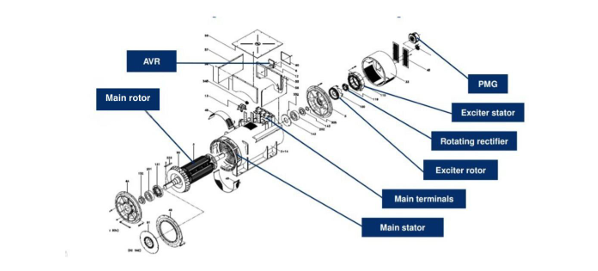

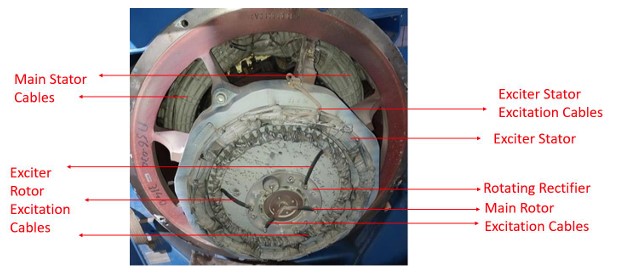

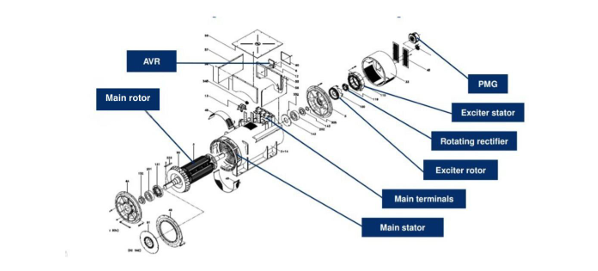

Main Components

PMG (Permanent Magnet Generator)

A PMG is a synchronous generator that has its own stator and rotor external to the main synchronous generator. The PMG rotor supports movement mounted on the main rotor. As a result of the PMG rotor’s movement, a voltage is induced in its own stator. This voltage supports the AVR card. The main purpose of using a PMG is to protect the AVR card.

AVR (Automatic Voltage Regulator)

The AVR is an electronic device that works either analog or digitally to ensure that the synchronous generator output voltage remains at a specified value. It provides voltage control based on the load of the synchronous generator. If the AVR card fails, excitation loss occurs in the alternator, and voltage production may stop.

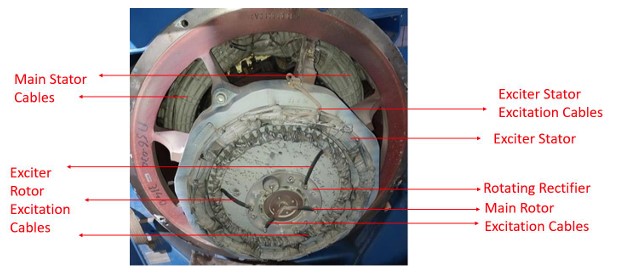

Rotating Rectifier

The exciter is a component that transmits voltage from the rotor to the main rotor using diodes. The AC voltage generated by the exciter rotor is rectified with diodes and converted into DC voltage.

Exciter Stator

The exciter stator is the part where excitation is performed with the help of the AVR card. After excitation, DC voltage is generated in the exciter stator.

Exciter Rotor

The exciter rotor works in conjunction with the exciter stator, facilitating the excitation process.

Main Rotor

The main rotor rectifies the AC current generated in the exciter rotor using the diode tray and transmits it as direct current. AC voltage is induced in the main stator due to the changing magnetic fields generated by the rotor’s motion.

Main Stator

AC voltage is induced by the excitation voltage from the main rotor. The induced voltage is supplied to the grid or power plant.

Terminal Board

The voltage induced in the main stator is connected to the grid using busbars. Currents passing through the cables are measured using current transformers.

Routine Controls of Synchronous Generators

Routine control of synchronous generators is essential for reliable and efficient operation.

Daily Checks

Daily checks aim to detect unexpected failures and prevent production loss. Some of the main daily checks include:

- Voltage Control

- Frequency Control

- Power Factor Control

- Synchronization Checks

- Bearing and Winding Temperature Monitoring

Daily checks help detect failures early to maintain operational continuity. Some of the common failures detected include:

- Defects in the AVR card

- Defects in the diode detection

Periodic Checks

Periodic checks are performed to ensure long-term reliability and efficiency. These include:

- Measuring the insulation resistance of the windings in the synchronous generator

- Measuring the internal resistance of the windings

- Measuring gaps in the rotating movement area of the main rotor and checking limit values

- Checking diodes in the rotating rectifier and measuring their resistance values

- Inspecting synchronous generator heaters

- Checking the equipment and connections in the terminal box

Periodic inspections help detect potential faults early, allowing for timely maintenance and reducing the likelihood of high-cost repairs.

Conclusion

Regular maintenance of a synchronous generator helps prevent high-cost problems by detecting faults early. This reduces unexpected failures, minimizing downtime and production losses. Efficient maintenance improves operational continuity, ultimately increasing the profitability of a business.

| Author: Muhammed Hakan KARACA

Title: Electrical Engineer / Field Service Engineer

Company: ILTEKNO A.Ş. |